Material topic

- Resource use and circular economy

Packaging

Our long-term goal is to support the circular economy and address environmental risks by employing sustainable packaging solutions that can deliver results from source to disposal. Our focus areas are the use of recycled materials and design for recyclability. The sourcing of pulp- and paper-based materials that are PEFC or FSC certified will help us to improve our supply chain impacts. Due to various challenges we have encountered (see below), progress towards our targets has been slower than expected and planned. This has required us to adjust our targets. We are aiming to design over 90% of our packaging to be recyclable by 2025 (previous target: 100%).

Sustainable Packaging Initiative

Our Sustainable Packaging Initiative considers impacts throughout the lifecycle of the packaging, from raw material sourcing to designing for recycling.1

We integrate environmental criteria in the packaging design process, alongside other criteria such as food safety, quality, and cost. Changes in the material composition to (re)design our packaging to make it recyclable and to use recycled materials are checked and approved by external laboratories and consultants, e.g., external certification of sorting and recycling compatibility. Food safety aspects are analyzed via external research to ensure that new materials and packaging solutions do not negatively impact our chocolate products. To achieve machineability and fulfill production process requirements, we perform extensive production and transport tests. We continuously proactively challenge our product portfolio by considering ways to reduce packaging material weight and packaging waste in production, and to minimize packaging destruction.

To achieve our five Sustainable Packaging Commitments, we are working to improve the packaging in which the products are sold to the customer (Consumer Units), that are used to transport the products to the stores (Transportation Units), and in which the products are placed in the stores for presentation (Display Units).

For the Sustainable Packaging Initiative, we have ten technical working groups, comprised of multinational internal experts who collaborate to find solutions. Their main focus is to identify materials and technologies that can help us fulfill our commitments and maintain our standards. The teams are working on different packaging solutions, including twist-wrapping, block bottom bags, praliné trays, flowpacks, and transportation trays. Their goal is to exchange and utilize the learnings and results of the tests. These expert groups can be considered as control committees proposing new solutions.

We have an internal guidance document on sustainable packaging and use a Lindt & Sprüngli recyclability assessment tool to locally assess the recyclability with a “traffic light” approach. This is updated annually by the external experts Interseroh+ “Made for Recycling”.

Our five Sustainable Packaging Commitments to support the circular economy

Challenges to our Sustainable Packaging Initiative

The baseline targets we set in 2020 have been affected by a changing product mix, in particular the increase in gifting. Furthermore, we are facing challenges in finding long-term sustainable packaging solutions, including extended lead times for trial materials, scalability of new technologies, and quality that meets our high standards. Our Sustainable Packaging Initiative addresses Lindt & Sprüngli’s impact throughout the entire packaging lifecycle. Good local infrastructure for collecting, sorting, and recycling packaging material, as well as enhanced consumer behavior, remain crucial elements of effective recycling processes.

While we will continue to make significant efforts to progress in the development of more sustainable packaging solutions, also in the light of upcoming regional legislation (mainly in the European Union), we have restated certain packaging targets in order to reflect the described circumstances. To increase our knowledge of the design of recyclable packaging, and to support fundamental research, we have joined two industry organizations. CEFLEX focuses mainly on plastic and composite based packaging; 4evergreen is an alliance for the fiber-based packaging value chain where we gain insights from industry peers to help us tackle the challenges we face.

Circularity performance

In the areas of packaging made from recycled materials, there was little deviation in our performance compared to the previous year. In 2023, 42.1% of our packaging was made from recycled materials. The decline compared to 2022 is attributable to the changes in product mix, in particular the increase in gifting, and improved reporting and data. Our relative share of virgin plastic remained relatively stable, decreasing from 10.0% in 2022 to 9.9% in 2023. We have taken important steps to increase recycled materials in our packaging, but finding alternative solutions that comply with strict food safety requirements remains challenging. This requires intense quality testing prior to implementing new materials. A slow scale-up usually takes place after implementation.

We increased our share of recyclable packaging from 88.3% in 2022 to 89.7% in 2023. The share of plastic packaging designed to be recyclable rose from 41.5% to 53.9%. We implemented local projects in several subsidiaries, mostly by gradually phasing out non-recyclable plastics.

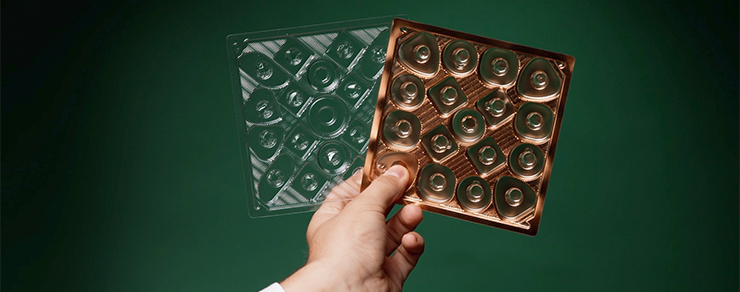

Recyclable praliné trays

The introduction of our new, transparent praliné trays for selected product lines in 2023 demonstrates our move towards designing packaging to be recyclable. To meet the latest recycling guidelines, we substituted colored metalized material with clear, uncolored PET. The trays contain between 30% and 80% of recycled material and can be recycled where local infrastructure is available and used. As the new trays require modifications on production lines, it will take several years to achieve a complete switchover across all subsidiaries.

Ongoing research and development (R&D)

In 2024, we will continue our activities, focusing in particular on circular design. We do long-term research on paper-based praliné trays, although we cannot yet forecast when these will be market-ready in scale. Extensive testing in redesigning our block bottom bags to a recyclable solution is ongoing. We are cooperating with start-ups in the area of recyclable and biodegradable plastics to identify potential applications, such as functional coatings, to enable new solutions.

We will continue to conduct research and development, along with production testing, to drive meaningful progress through the next few years on key packaging-related issues. These include reducing the use of plastic and finding alternatives to non-recyclable composite materials and hard-to-recycle plastic wrappers and trays. For this we do not only partner with direct suppliers, but also with tier 2 suppliers to learn more about their new technologies and solutions.

1 16 While our Sustainable Packaging Initiative addresses Lindt & Sprüngli’s impacts along the complete packaging life cycle, it is important to note that the availability of proper local infrastructure and markets for collecting, sorting, and recycling packaging material – as well as enhanced consumer behavior – must exist where our products are consumed for the objectives to be realized. We consider a material as recyclable based on a developed collection and sorting infrastructure at state-of-the-art technology on an industrial scale.